Process development & prototype production

- Matthias Bünck

- +49 241 94324934

- m.buenck@access-technology.de

The driving force of innovation

Access e.V. offers the professional and industry-oriented development of casting processes and the casting of prototypes and small series – both as part of publicly funded projects and as direct contract work. For optimum customer benefit, Access e.V. works in accordance with the quality standard of aviation EN 9100. Qualified personnel, state-of-the-art equipment along the entire production chain and the latest methods of digital data acquisition ensure short development times and the highest possible customer satisfaction. Access has the equipment to process almost all common as well as exotic casting alloys in fine and gravity die casting processes under heavy and centrifugal force. Access focuses in particular on the processing of high-temperature materials based on nickel, titanium and iron. In addition to broad-based research and development, Access e.V. operates Access GmbH, which serves to industrialize new developments.

Work steps in process development and prototype production:

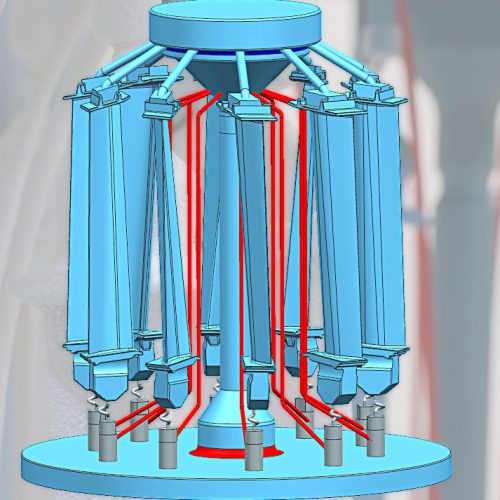

Technology & Simulation

In the industry-oriented development of casting processes, prototypes and small series, achieving optimum casting properties is always the top priority for Access e.V.. Supported by a wide range of simulation systems, depending on

- Quantity,

- Material and

- Component specification

the preferred manufacturing technology.

The respective technology can be simulated and optimized for specific applications. Digital twins of the process and product can be used to, for example:

- sprue and feeding system can be designed for casting using mold filling and solidification simulations.

- Mechanical properties of the casting can be determined and optimized by simulating the microstructure and microstructure.

Geometric optimizations are possible using the latest reverse engineering software.

Access e.V. offers industrial process development according to aviation standards in the high-tech sector, both as direct contract work or as a partner in research projects. The focus is on the development of industrially usable processes for the casting production of components up to series maturity (TRL 6).

Modern gravity, centrifugal and low-pressure casting systems form the heart of the complete process chains for fine and permanent mold casting processes on an industrial scale that have been set up in the Access TechCenter on an area of 3,800 m². Specializing in high-performance metallic materials, which place very high demands on casting processing, Al, Ti, Fe, Ni, TiAl, FeAl alloys and High Entropy Alloys (HEA) are processed.

A high degree of automation and digital data acquisition along the entire process chain enable the development of ultra-modern, efficient and environmentally friendly processes.

Process development

Prototype casting

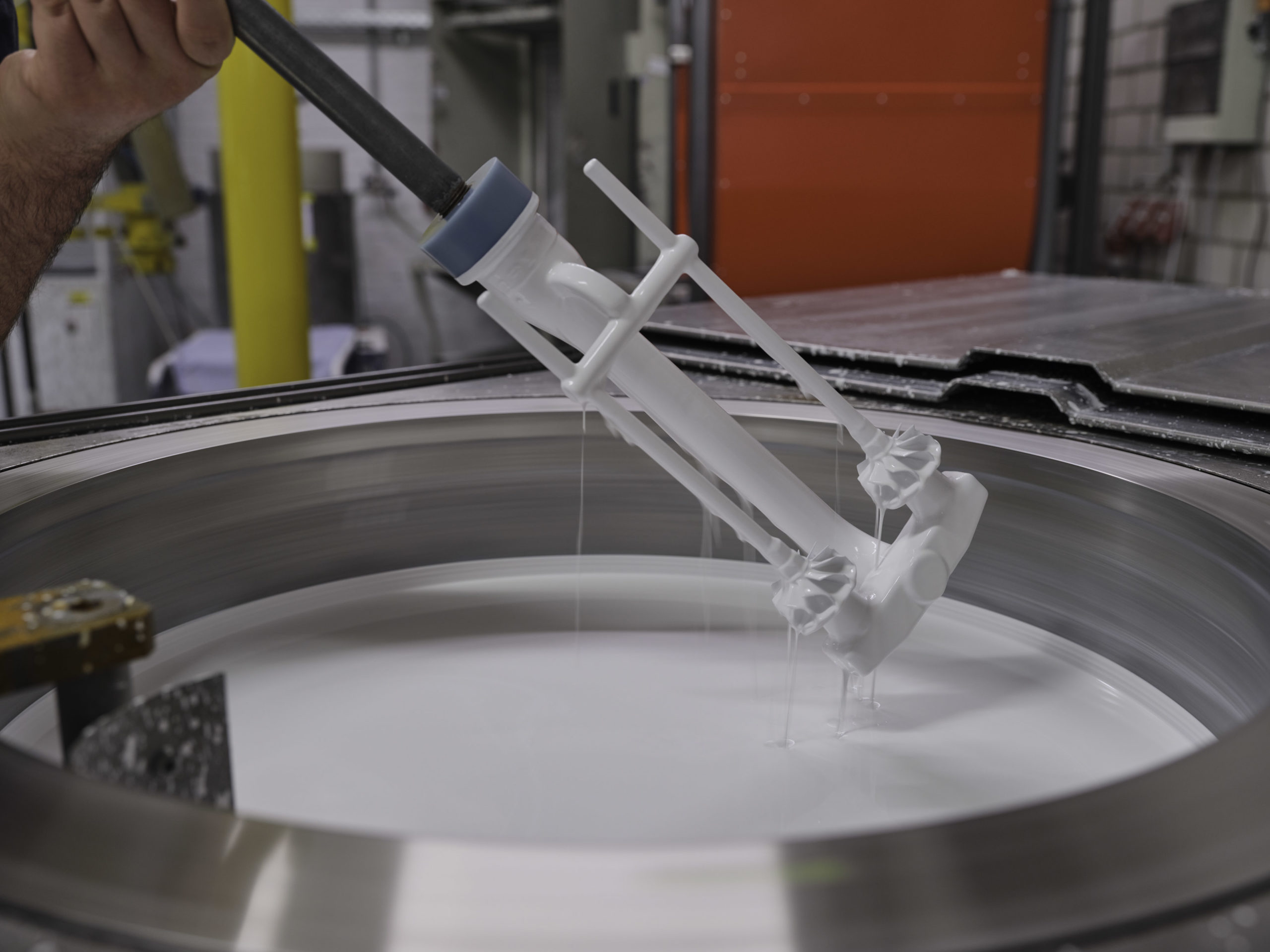

Access e.V. manufactures prototypes using the lost wax process and gravity die casting and has a comprehensive industrial and semi-automated production chain as well as extensive laboratory equipment. Individual pieces and small series can be produced from a wide variety of materials using a modern, fully automated ceramic line. This includes, among other things

- Conventional, reactive and particle-reinforced aluminum alloys

- Refractory alloys based on iron, cobalt, nickel and titanium

- Intermetallische Legierungen und High Entropy Alloys (HEA)

Different models are used depending on the requirements for surface quality, geometric accuracy and quantity:

- Wax models from matrices

- 3D printed wax models

- 3D printed plastic models (PMMA)

Wax matrices and molds can be manufactured at Access. Depending on the requirements, heat treatment and mechanical processing are carried out downstream. All process steps are documented and monitored in accordance with aviation quality management EN 9100.

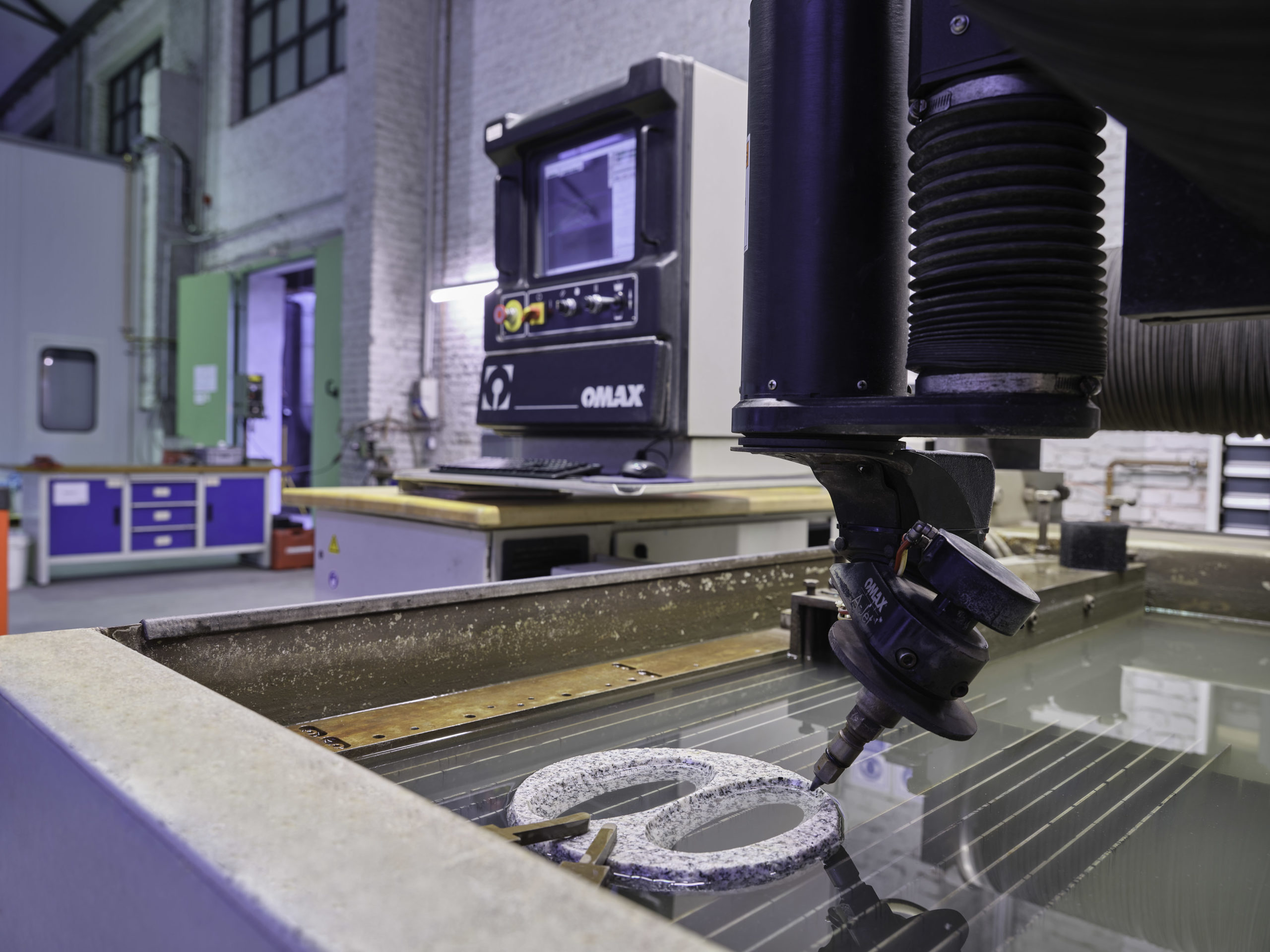

The components manufactured at Access e.V. pose challenges for mechanical processing in terms of material and shape. Starting with the separation of the complex 3D geometry from the running and feed system using the water jet cutting process, through the manufacture of devices for holding and fixing the components in the various machining steps, to the final machining of complex flow profiles, Access covers the manufacturing process. Furthermore, the equipment used in the processes, such as

- Matrices for the production of wax models

- Molds for the gravity die casting process

- Samples for quality assurance

The entire portfolio of machines available for processing at Access can be found in the equipment list.

Mechanical processing

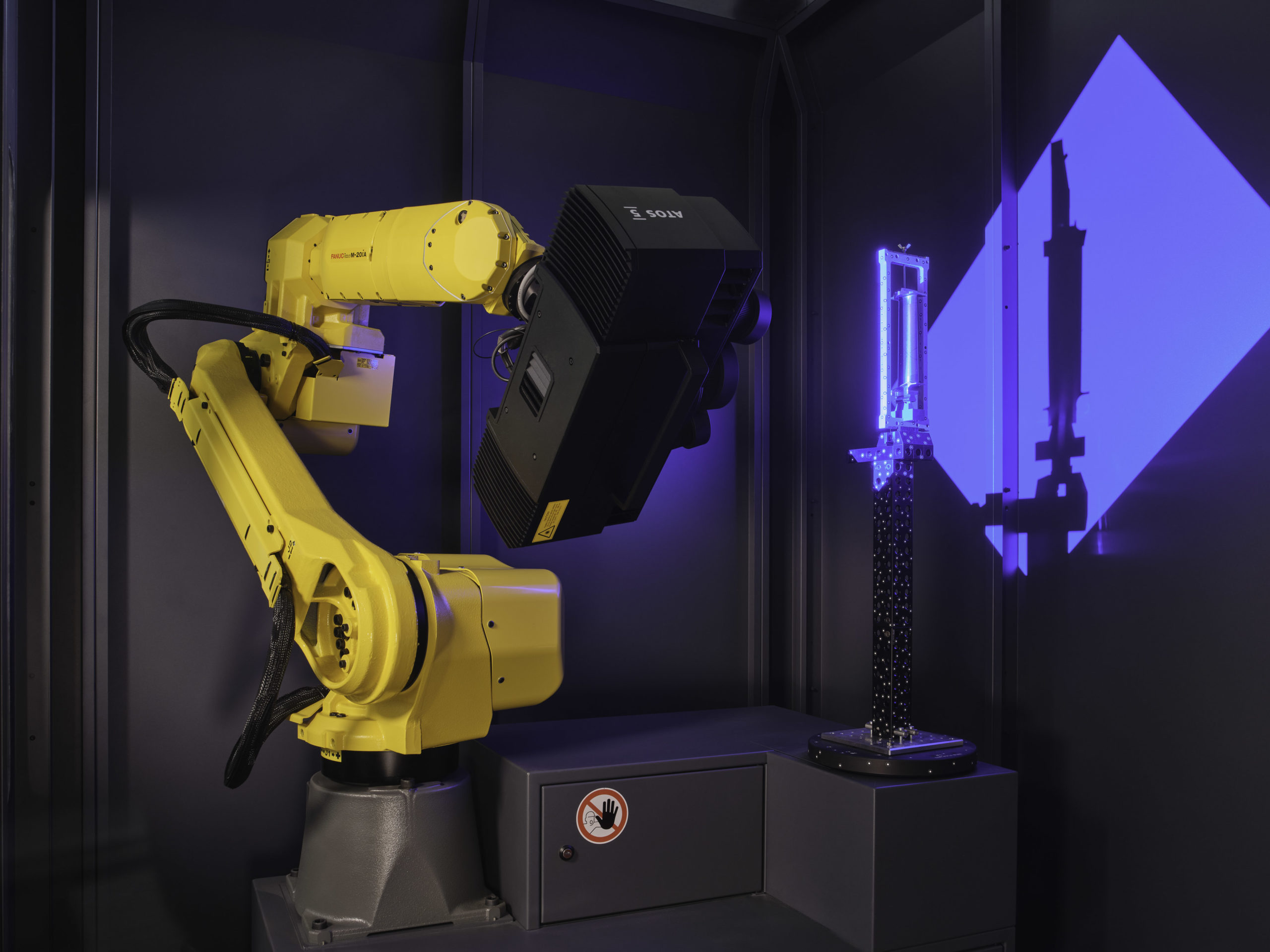

Quality assurance

Quality assurance is an inherent part of the ongoing production processes in the TechCenter at Access e.V. This includes both ensuring that customer requirements are met throughout the entire process chain and continuously improving processes by evaluating process data using statistical methods. This includes, among other things

- Karl Deutsch Fluorescent penetrant inspection (FPI)

- GOM ATOS 3D Scanbox

- Nikon XTEK XT H 320 LC Computertomograph (CT)

- Spectro SPECTROLAB S spark spectrometer

- Zwick/Roell Z030 THW Allround Line high-temperature testing machines

- Zwick/Roell KAPPA 50 DS creep testing machine

Quality assurance begins with the quality management-compliant incoming analysis of raw materials and spans all areas of production from model production to the finished component. This is done in individual measurements as well as continuously online.

In addition to ensuring the highest quality standards, the modern measuring methods at Access e.V. are also used extensively in process development and for measurements on behalf of customers.

A complete list of the measuring methods and tools available at Access e.V. can be found in the equipment list.

The driving force of innovation

Access e.V. offers the professional and industry-oriented development of casting processes and the casting of prototypes and small series – both as part of publicly funded projects and as direct contract work. For optimum customer benefit, Access e.V. works in accordance with the quality standard of aviation EN 9100. Qualified personnel, state-of-the-art equipment along the entire production chain and the latest methods of digital data acquisition ensure short development times and the highest possible customer satisfaction. Access has the equipment to process almost all common as well as exotic casting alloys in fine and gravity die casting processes under heavy and centrifugal force. Access focuses in particular on the processing of high-temperature materials based on nickel, titanium and iron. In addition to broad-based research and development, Access e.V. operates Access GmbH, which serves to industrialize new developments.

Work steps in process development and prototype production:

The driving force of innovation

Access e.V. offers the professional and industry-oriented development of casting processes and the casting of prototypes and small series – both as part of publicly funded projects and as direct contract work. For optimum customer benefit, Access e.V. works in accordance with the quality standard of aviation EN 9100. Qualified personnel, state-of-the-art equipment along the entire production chain and the latest methods of digital data acquisition ensure short development times and the highest possible customer satisfaction. Access has the equipment to process almost all common as well as exotic casting alloys in fine and gravity die casting processes under heavy and centrifugal force. Access focuses in particular on the processing of high-temperature materials based on nickel, titanium and iron. In addition to broad-based research and development, Access e.V. operates Access GmbH, which serves to industrialize new developments.

Work steps in process development and prototype production:

The driving force of innovation

Access e.V. offers the professional and industry-oriented development of casting processes and the casting of prototypes and small series – both as part of publicly funded projects and as direct contract work. For optimum customer benefit, Access e.V. works in accordance with the quality standard of aviation EN 9100. Qualified personnel, state-of-the-art equipment along the entire production chain and the latest methods of digital data acquisition ensure short development times and the highest possible customer satisfaction. Access has the equipment to process almost all common as well as exotic casting alloys in fine and gravity die casting processes under heavy and centrifugal force. Access focuses in particular on the processing of high-temperature materials based on nickel, titanium and iron. In addition to broad-based research and development, Access e.V. operates Access GmbH, which serves to industrialize new developments.

Work steps in process development and prototype production: