Material development

- Ulrike Hecht

- +49 241 8097332

- u.hecht@access-technology.de

Access develops new alloys for conventional, additive and hybrid manufacturing processes: Our expertise includes thermodynamic calculations, fundamental investigations of microstructure formation, comprehensive material characterization and testing. We are specially equipped to work with miniature samples, so that small quantities of material are sufficient in the development phase.

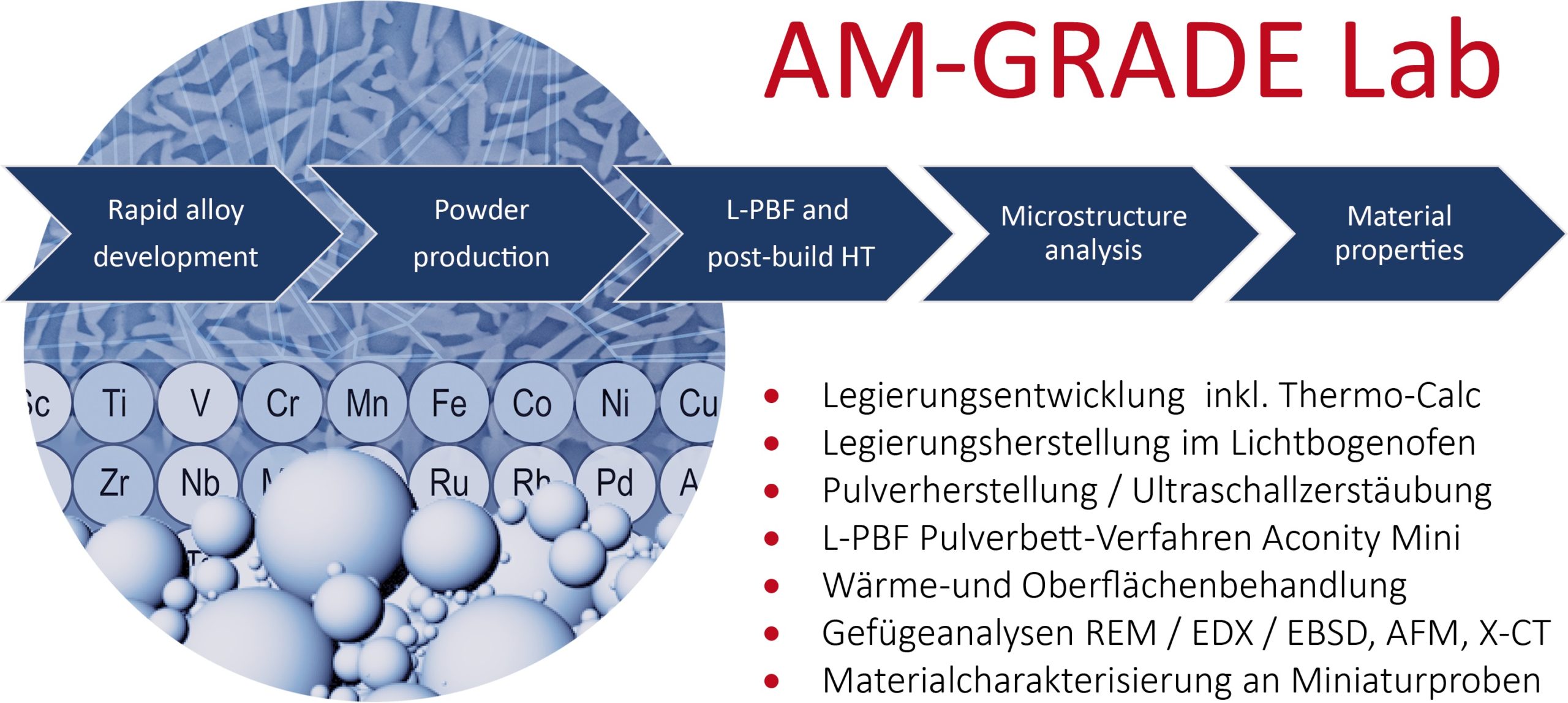

- AM-Grade Lab for powder-based AM materials

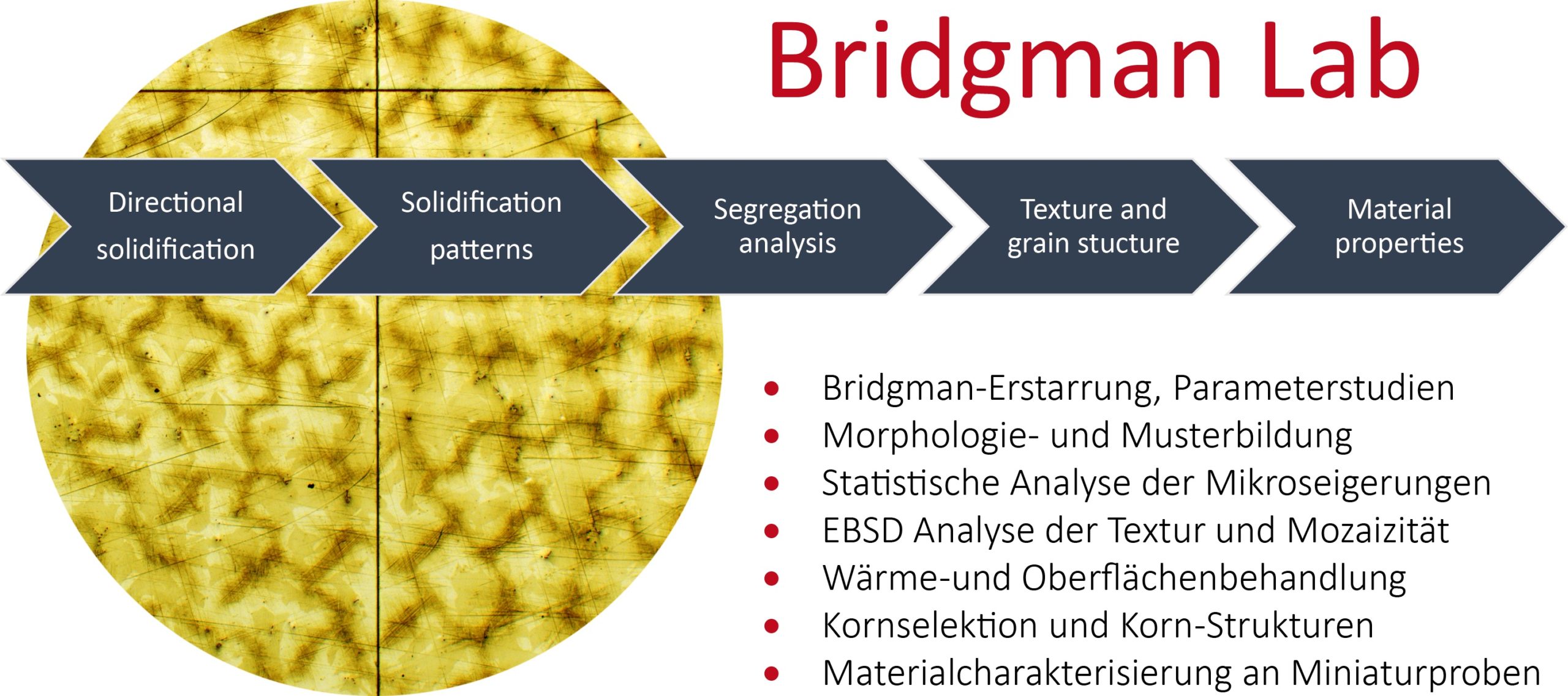

- Bridgman-Lab for straightened and single-crystal materials

- New duplex materials made from high-entropy alloys

- In-situ composites and dispersion-reinforced materials

- MAX phases and composites: Ti2AlN, Ti2Al(N,C)

New materials for laser-based additive and hybrid manufacturing are developed in the highly integrated AM-Grade Lab. Some of these are also ideal for casting and other powder-based manufacturing processes. AM-Grade covers all manufacturing steps from powder production to material testing on miniature samples. Top-end equipment and software are available for the characterization of microstructures and material properties, as well as numerical models and simulation tools.

The Bridgman lab is used to investigate and optimize the directional and, if necessary, monocrystalline solidification of alloys, e.g. for Ni-based superalloys or shape memory alloys. The Bridgman technique is also ideal for heat treatments in temperature gradients and can replace complex series of experiments.