Products & Services

Access offers an extensive portfolio of services and products in research and development. Dies umfasst die gesamte Prozesskette von der Werkstoffentwicklung bis zur Qualifizierung von Kleinserien und Funktionsprototypen. Auch bei der Optimierung bestehender Prozessketten kann Access Sie z.B. durch skalenübergreifende Simulationen auf Mikro- und Makroebene unterstützen. Als langjährig erfolgreiches Forschungsinstitut unterstützt Access Sie gerne bei der Beantragung öffentlicher Projekte.

Access also sells various products. These include the MICRESS software package developed in-house, for example, but the product range also includes molds and crucibles for investment casting processes.

Analytics

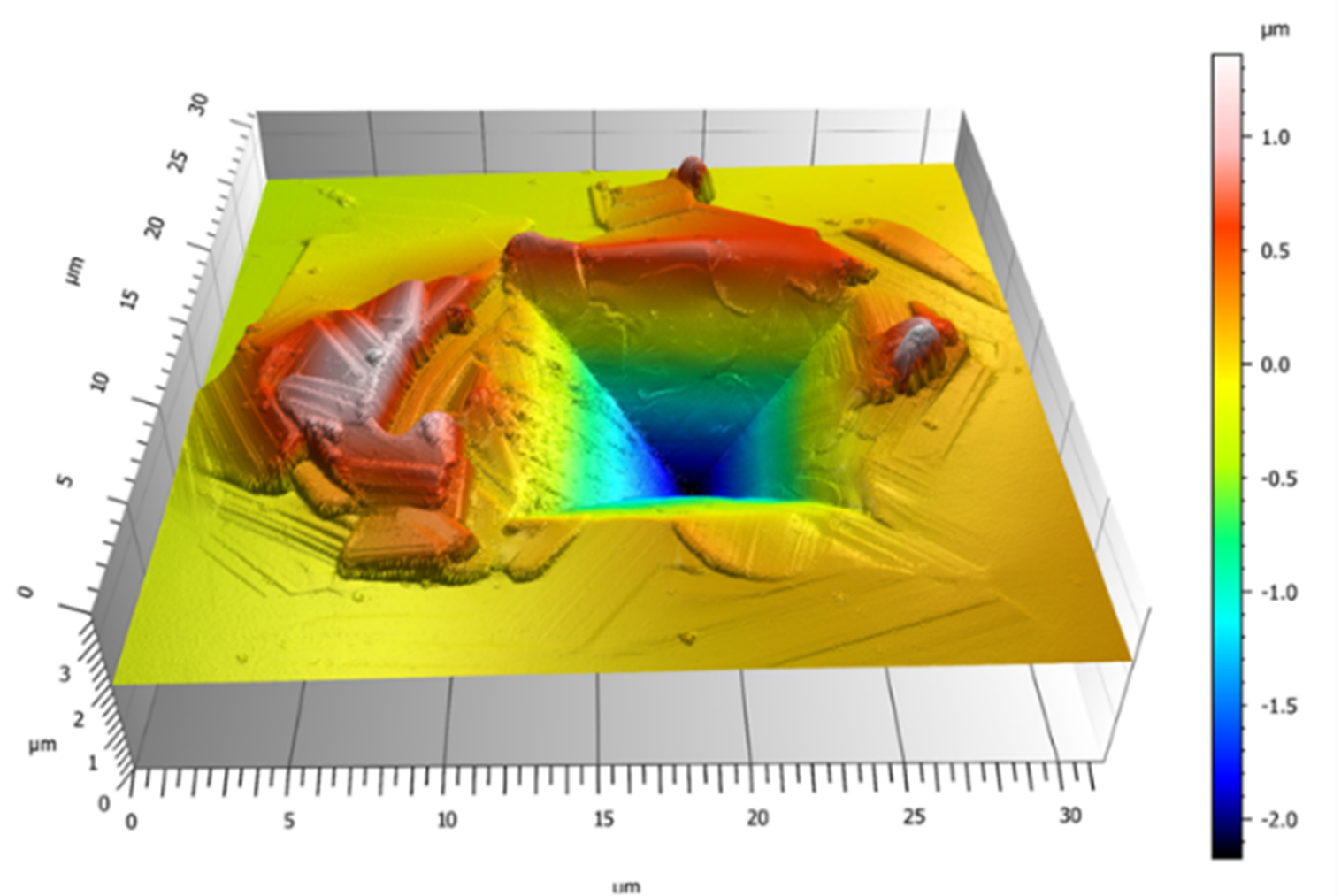

Spread over three laboratories, Access e.V. offers a comprehensive range of analytical services with a focus on microscopy, computed tomography and micromechanical characterization. Three Zeiss FE-SEMs offer the possibility of analyzing microstructures, phases, texture and grain size (EBSD) and chemical composition (EDX) as well as the possibility of creating element distribution maps with a resolution down to the nanometer range using state-of-the-art EDX detectors. Digital light microscopy (HIROX) offers the possibility of multi-focus analysis for the creation of 3D images and surface profiles. A TOSCA AFM (Anton-Paar) can be used to image the profiles of nanostructured surfaces and nanomechanical characteristics. Sample preparation and the qualitative and quantitative description of the microstructure of a wide range of materials can be carried out in our well-equipped metallography department. An industrial computer tomograph (CT) from Nikon offers the possibility of non-destructive 3D analyses for quality assurance down to the 10 micrometer range. In addition to the above-mentioned aspects, our analytics department offers extensive software (MATLAB/MTEX, ImageJ, Volume Graphics, Keras/TensorFlow, VG-Studio Max), in combination with trained knowledge and a lot of experience, also in the field of digital image analysis.

Process development & prototype manufacturing

Access e.V. has comprehensive state-of-the-art investment casting equipment on an area of 3800 square meters. In view of its strong focus on aerospace applications, Access e.V. works in its TechCenter with the aim of providing optimum customer benefit in accordance with the aerospace quality standard: EN 9100. The TechCenter offers interested customers the possibility of prototype production according to customer specifications. The comprehensive quality assurance and analytical equipment as well as the processing machines can be used for the benefit of the customer. Access e.V. offers both the manufacture and testing of individual products or small batches as well as the development of complete production technologies.

Microstructure simulation

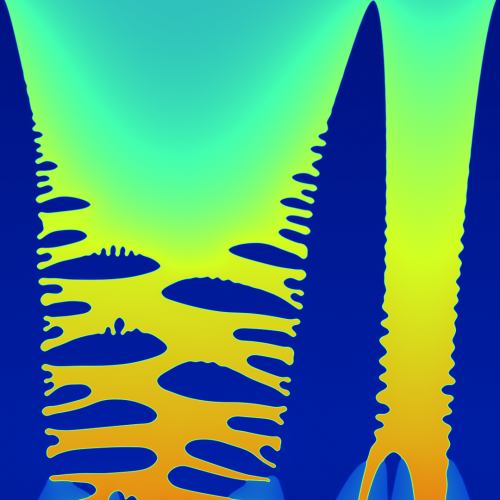

Access offers software and simulation calculations in the field of microstructure development of metallic materials:

- MICRESS® – MICRostructure Evolution Simulation Software – a software package for the simulation of microstructure evolution in metallic materials. MICRESS was developed by Access and has been used by licensees in Germany and abroad since 2004.

- HOMAT – a software for calculating effective material properties of heterogeneous materials based on the asymptotic homogenization method. HOMAT is developed by Access and has been distributed under license since 2015.

- Simulation calculations on behalf of customers, in particular the development of customised simulation scenarios for MICRESS and HOMAT, which enable the rapid implementation of independent simulation calculations for customers.

- Support of material and process development with the methods of microstructure simulation.

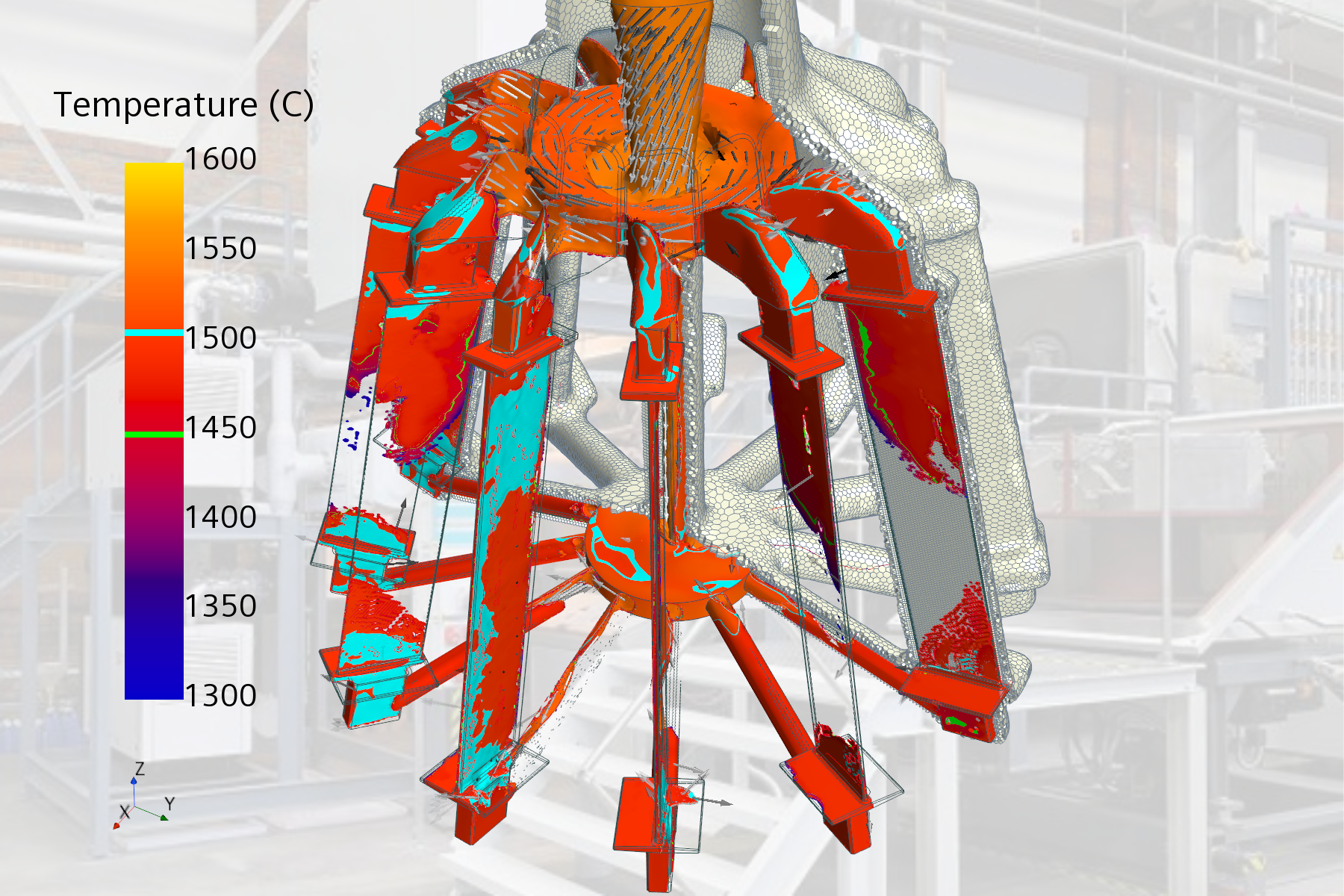

Process simulation

Access has 30 years of experience in supporting industrial partners with the simulation of metallurgical processes. In particular, we have extensive experience in the simulation and optimization of:

- Casting processes: Investment, pressure, low-pressure and sand casting

- flow processes: Filling, mold filling, tempering

- Thermal processes: Solidification/crystallization, heat treatment, Bridgman process, quenching

- Additive processes: Powder and wire based processes

Access uses the following commercial programs to simulate and optimize these manufacturing processes: STAR-CCM+, Magmasoft and Abaqus.

Some of these are adapted to the special requirements of the manufacturing processes by our own extensions and supplemented by software solutions developed in-house. Together, this enables the coupled calculation of flow, temperature distribution, stress build-up and distortion for many alloy systems (light metals, steel, cast iron, Ni-based superalloys, TiAl, FeAl,…).

The distribution of particles (inoculation, nanoparticles) and foreign matter (slag, eroded sand, oxides) can also be calculated. The cross-scale coupling of the simulation to MICRESS or a cellular automaton (CAFE model) enables the calculation of the microstructure and thus an estimation of mechanical properties.

Access is also happy to support you in the acquisition of experimental data using thermocouples, infrared cameras, flow analysis and other methods.

Application-orientated basic research

Model tests with defined process parameters can be carried out in various furnaces for material production, solidification or heat treatment of alloys. The range of materials includes low-melting organic alloys, which solidify in a metal-like manner, as well as a wide range of metallic alloys up to 1500°C melting temperature. The instrumented furnaces allow a targeted variation of process parameters and are partly equipped with decanting and stirring devices or optical and X-ray in-situ observation diagnostics.

For the prediction and interpretation of solidification structures, we also offer simulation tools together with other business areas, such as thermal simulations, flow simulations and microstructure simulations (phase field, envelope, dendrite needle network). In the medium term, we will also be using deep learning and AI methods to characterize microstructures.

Production of crucibles and moulds

Thanks to its many years of experience in investment casting and, in particular, the manufacture of molded shells, Access offers the production of high-quality crucibles and molded shells for standard dimensions and special customer requirements. Maximum diameters of 550 mm with a height of 500 mm can be processed. Frequent mold shells for customer orders are test bars for various test geometries (flat tensile test, tensile bars, etc.) or crucibles. Depending on the quantity, this can be done in the manual dipping area or on an automated ceramic line in the Access TechCenter. Depending on the alloy to be melted, shaped shells can be produced on the basis of aluminum oxide or yttrium oxide. In addition, we provide capacities for autoclaving, debinding or firing. Our molds can be used for gravity casting, centrifugal casting or the Bridgman process.

Advice on funding opportunities

We support cooperation partners in submitting applications for publicly funded projects from the following funding bodies:

- Federal government (e.g. BMWi, BMWF)

- State (NRW, Berlin-Brandenburg

- EU

We maintain contacts with the project sponsors:

- Euronorm

- DLR

- PT Jülich

- KIT

- VDI

- ILB

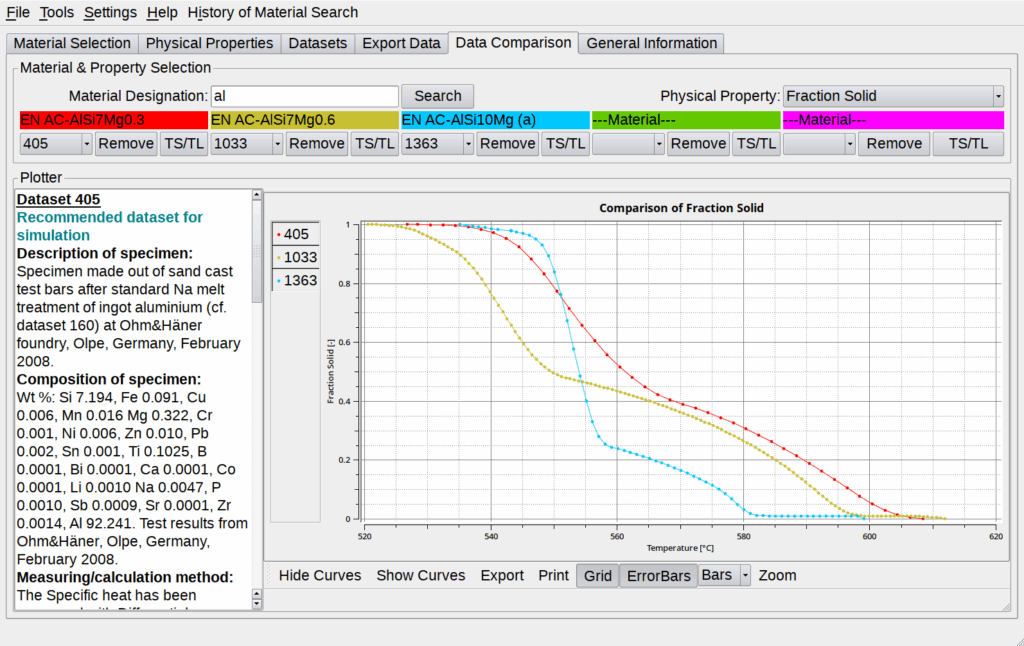

The accuracy of casting simulations relies heavily on the quality and completeness of the material data used. A database like AMat.Pro, which is of high quality , plays an indispensable role in achieving high-precision results. With this web service, engineers can now access and use AMat.Pro’s extensive inventory of validated material properties directly from their web browser.

For anyone involved in casting simulation, the availability of accurate and comprehensive material data is critical to providing reliable and trustworthy results. Accessing AMat.Pro via a web service simplifies the process of integrating these important data points into your projects.