Basics of solidification

- Laszlo Sturz

- +49 241 8098000

- l.sturz@access-technology.de

Since its foundation, Access e.V. has stood for research into the principles of solidification as part of publicly funded projects. The aim is to transfer knowledge into the development of casting processes, materials and modeling tools.

For basic and application-oriented investigations, various furnaces for tempering and defined solidification in temperature gradients are available in our own laboratory, both for low-melting organic materials and for high-temperature materials (up to 1800°C). In particular, the in-situ investigation of solidification phenomena using thermal sensors, optical methods or X-ray radiography in metallic samples is used. Close cooperation with the other business units enables the use and further development of the necessary analysis methods and simulation tools for the quantitative determination of characteristic structural parameters.

As a further important pillar, experiments under reduced gravity on parabolic flights, sounding rockets and the International Space Station ISS have been and are being carried out in mostly international projects in order to investigate solidification processes largely free of flow processes and thus generate indispensable benchmark data.

Artificial intelligence methods and mesoscopic modeling of solidification morphologies are increasingly being used as new tools. All of these approaches make it possible to better understand fundamental solidification phenomena and to transfer these findings to industrial applications.

Methoden der in-situ Diagnostik ermöglichen die orts- und zeitaufgelöste Beobachtung von Erstarrungsphänomenen

- X-ray radiography

- X-ray CT

- Optical microscopy

- Thermal sensors

The focus of the investigations is on

- Solidification dynamics

- Microstructure development

- Phase formation

- Defect formation

Examples of applications are

- CET in AlCu alloys

- CET in transparent model alloys NPG-DC

- Eutectic growth in AlCuAg

- Eutectic growth in NPG-DC-SCN-AMPD

- Crystal orientation in AlGe alloys

- Crystal orientation in transparent model alloys NPG-DC

- Monotectic segregation in BiZn

- Monotectic segregation in SCN-H2O

Modeling allows a better understanding of the physical principles and a transfer to other materials and processes

- Phase field simulations

- Solidification models

- Mesoscopic solidification simulations (Envelope, DNN)

- Scale coupling

The focus of the modeling is on

- Dendritic solidification

- Directional, non-directional growth

- Peritectic growth

- Flow influence on solidification

- Crystallographic orientation

Examples of applications are

- TiAl alloys

- Al alloys

- Transparent model alloys

Modeling

By loading the video, you agree to YouTube's privacy policy.

Learn more

Zero gravity

Phasenumwandlungen unter Schwerelosigkeit unterstützen die Modellbildung

- Parabolic flights

- Rocket experiments

- International Space Station

The focus of the µg experiments is on:

- Solidification without buoyancy and sedimentation

- Diffusive solidification without thermosolutal convection in the melt

- Investigation of various solidification phenomena, e.g. dendritic solidification, directional, non-directional growth, CET, peritectic growth

- Solidification under the influence of gravitational changes/hypergravity (0g – 2g)

Application examples are

- CET in AlCu, AlSi alloys

- CET and equiaxial growth in transparent model alloys NPG-DC

- Formation of intermetallic phases in AlSiFe alloys

- Eutektisches Wachstum in AlCuAgEutectic growth in AlCuAg

- Eutectic growth in NPG-DC-SCN

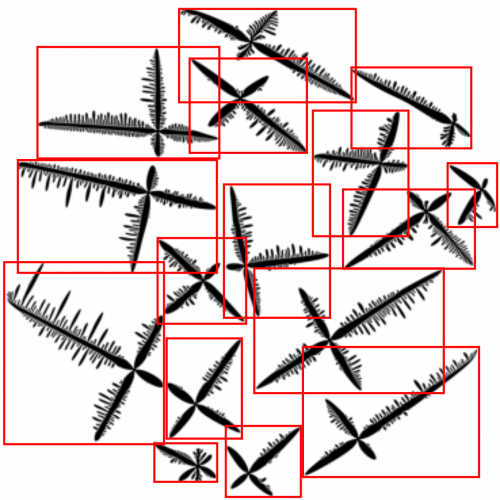

Development of customized AI methods for the characterization of different microstructure types

- Microstructure detection – and classification

- Automatisierung Künstliche Intelligenz und maschinelles Lernen erweitern klassische Analytik

The focus of AI deployment is on

- Development of customized AI methods for the characterization of different microstructure types

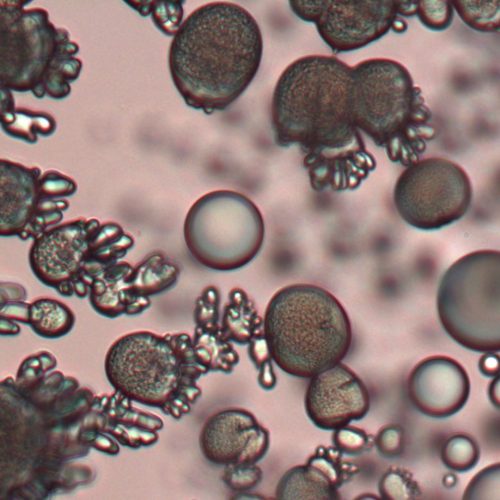

Application examples are

- Equiaxial dendritic solidification of a solid primary phase from a melt

- Columnar dendritic solidification of a primary phase with defects

- Phase separation in monotectic alloys

Artificial intelligence