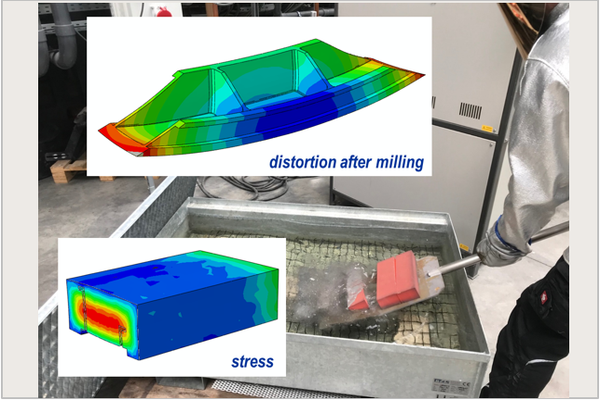

Prediction and compensation of component distortion due to residual stresses during 5-axis milling

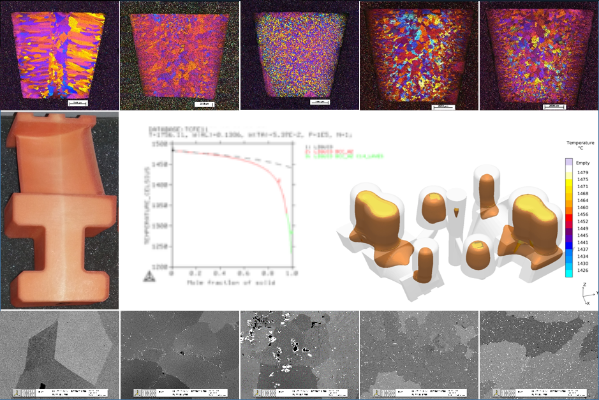

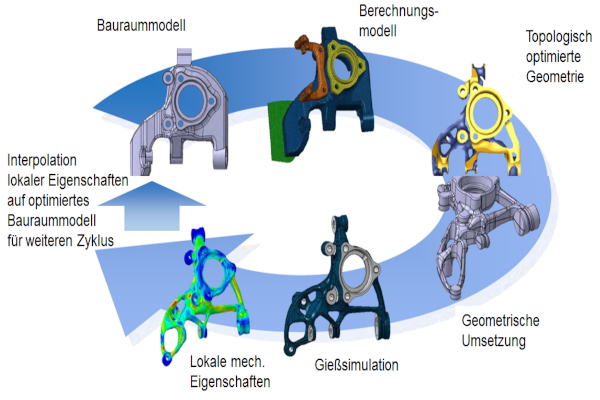

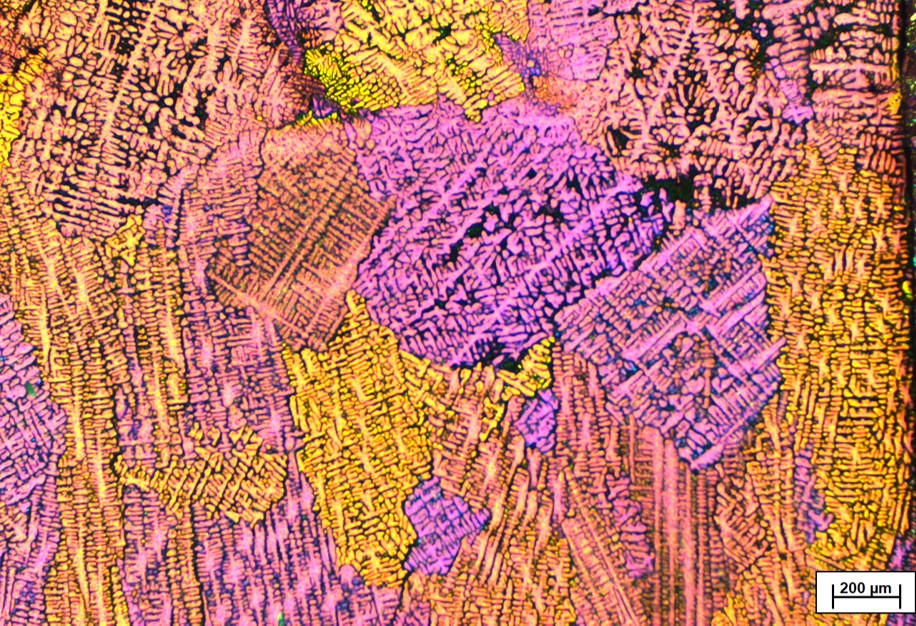

VoKoESPrediction and compensation of component distortions caused by residual stresses during 5-axis millingThe aim of the VoKoES research project is to improve the prediction and compensation of component distortions caused by residual stresses during 5-axis milling and in CAM programming. The following four lines are defined for this purpose: Development of a simulation to determine […]