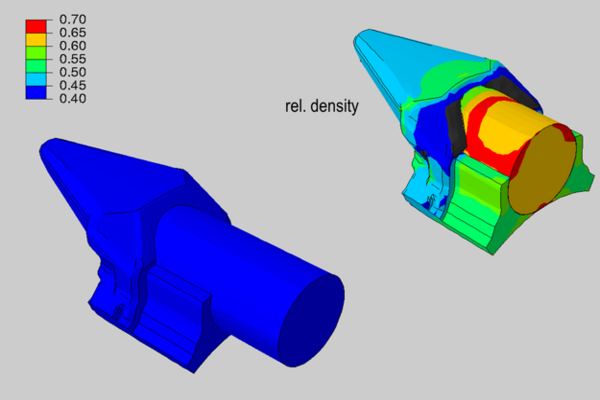

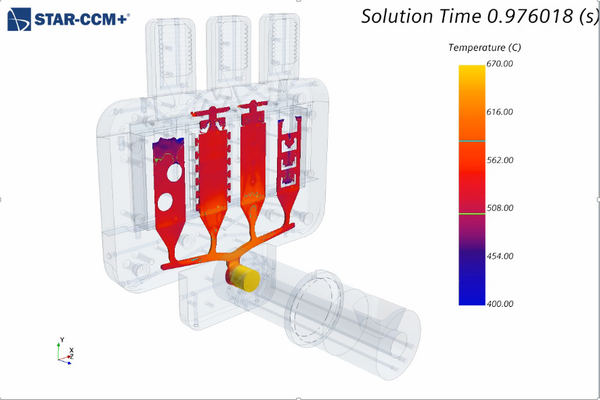

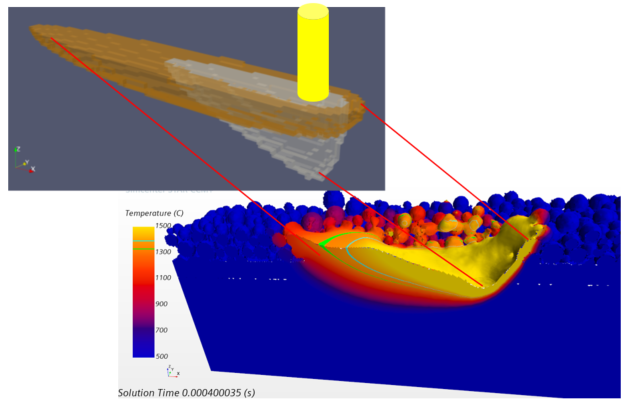

Press-IT process simulation

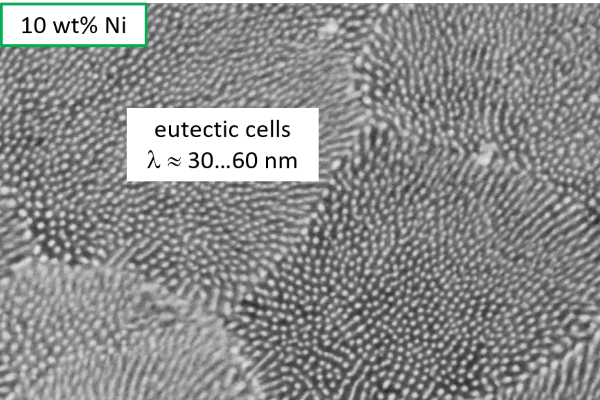

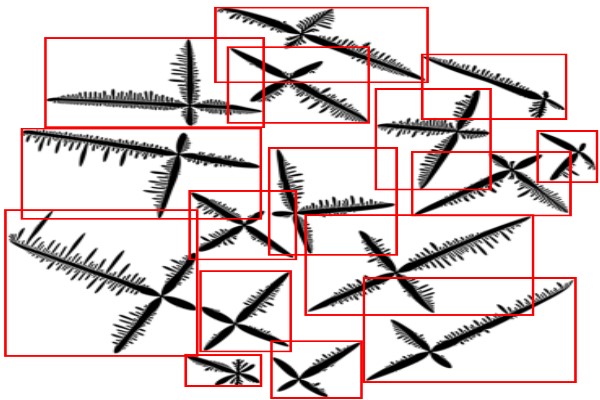

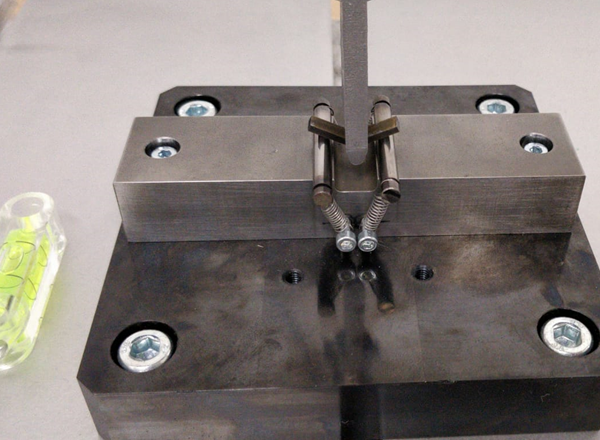

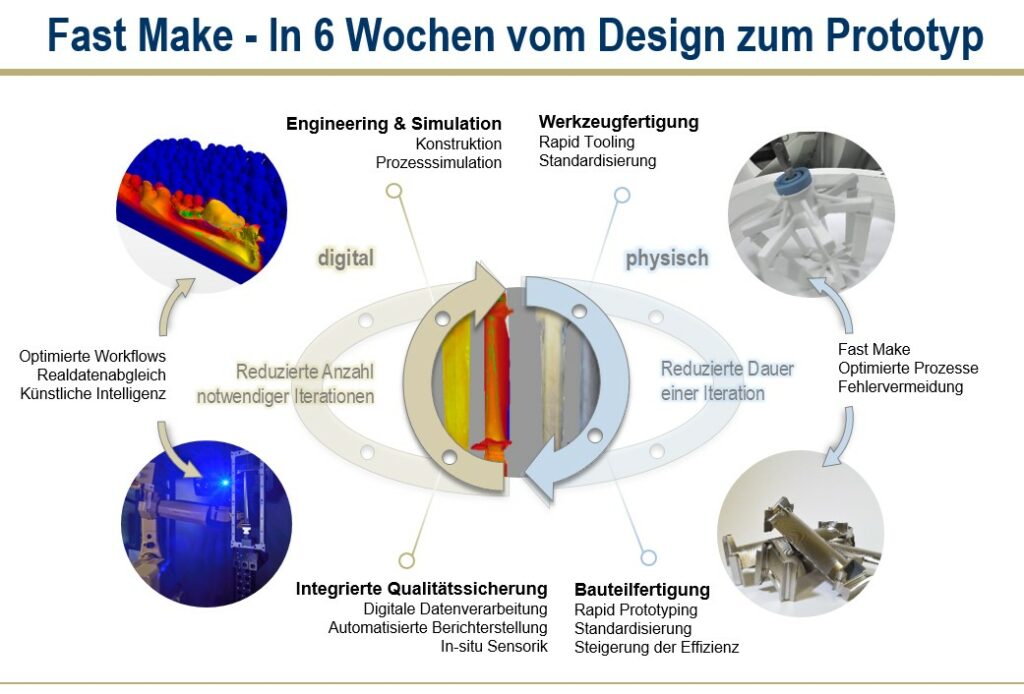

Press-ITPress-IT process simulationThe “Kochanek process” is a six-stage process for the production of nanocrystalline steel parts. The production route is CO2-free and no post-processing of the parts is necessary. The intended target product for industrial production in large quantities is a geometrically complex component from the electric motor: the claw pole. The “Kochanek process” (DE […]

Press-IT process simulation Read More »