Solidification of lightweight materials in weightlessness III

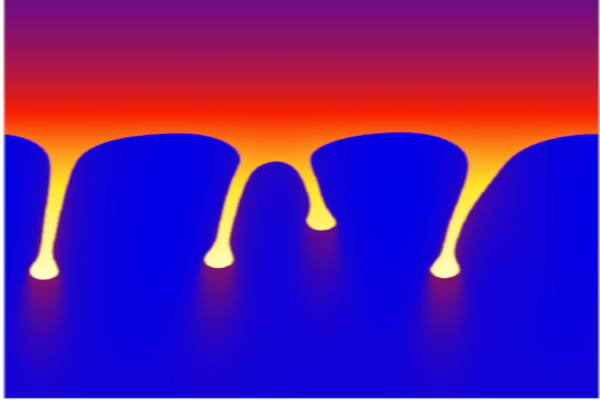

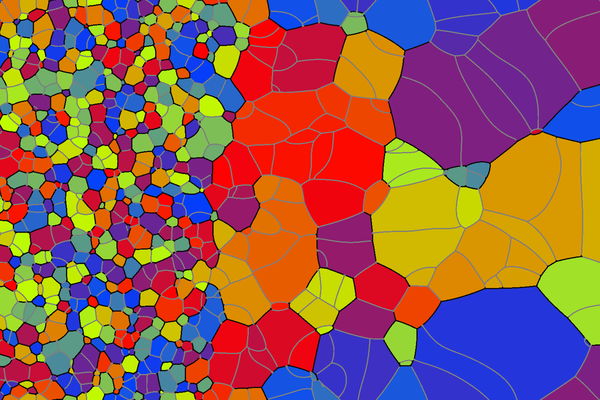

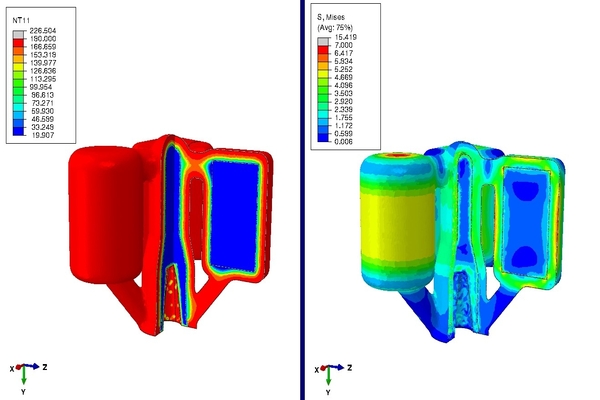

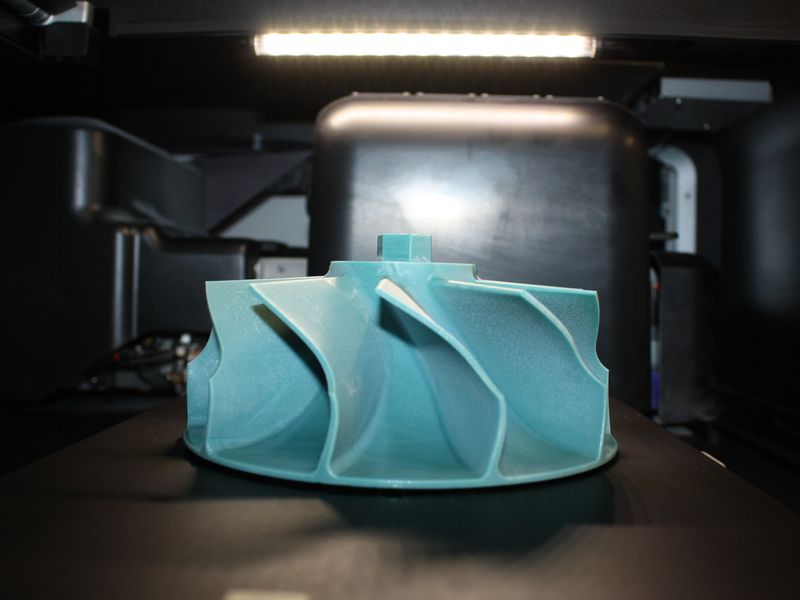

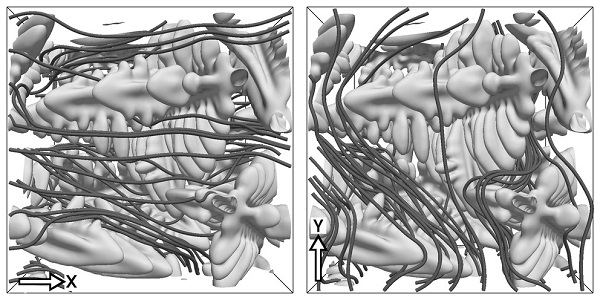

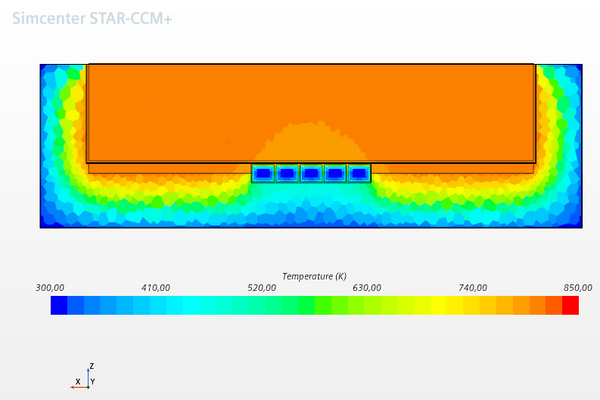

DLR ELIS-IIISolidification of lightweight materials in microgravity IIIThe aim of the project is to investigate and model the microstructure formation responsible for the material properties during solidification in different material classes, solidification forms and length scales. The focus is on dendritically solidifying materials, which are often typical for industrially manufactured components. The use of reduced […]

Solidification of lightweight materials in weightlessness III Read More »