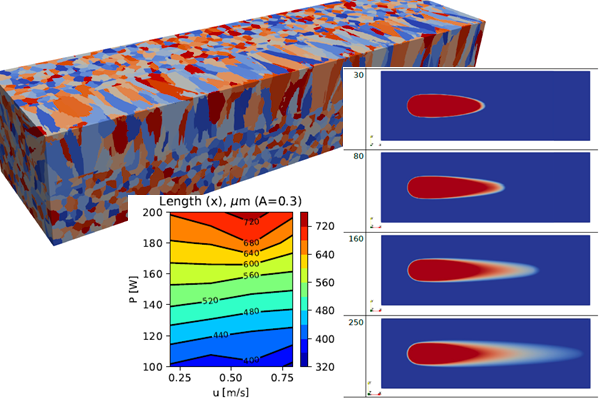

Lightweight construction concepts for cast structural components of wind turbines

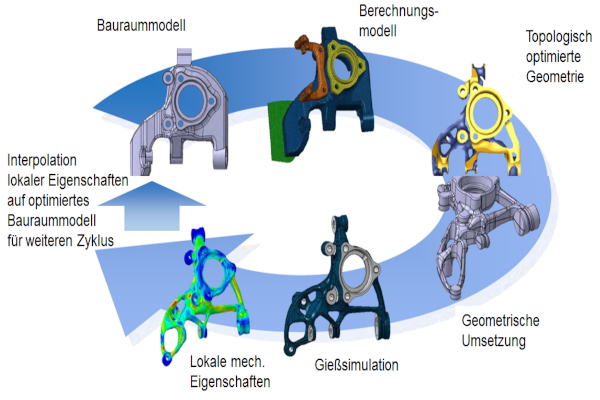

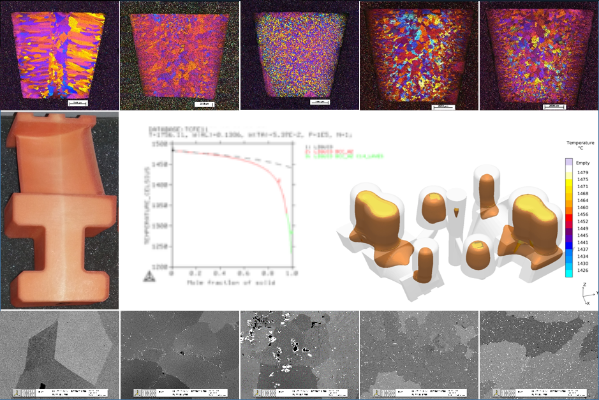

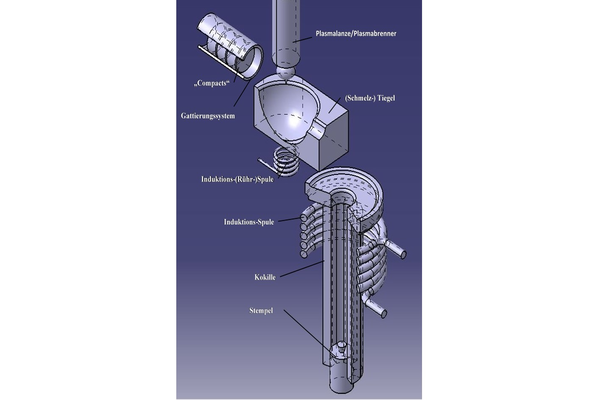

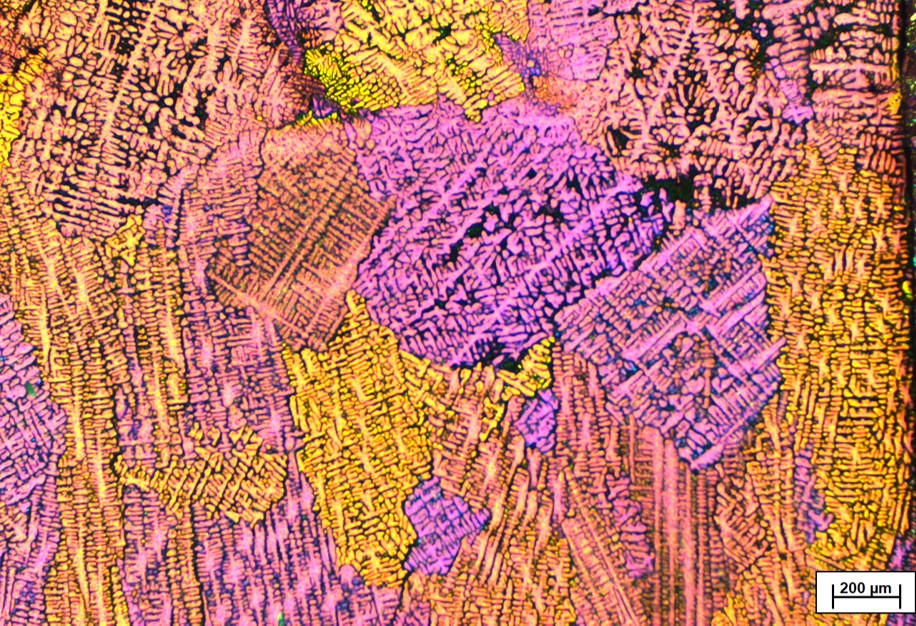

LeKoGussWEALightweighting concepts for cast structural components of wind turbinesThe continuous increase in the performance of wind turbines is accompanied by a continuous increase in the weight of the nacelle, which results in a variety of problems. The aim of the research project outlined here is therefore to reduce the weight of the cast structural components […]

Lightweight construction concepts for cast structural components of wind turbines Read More »